June 12, 2025

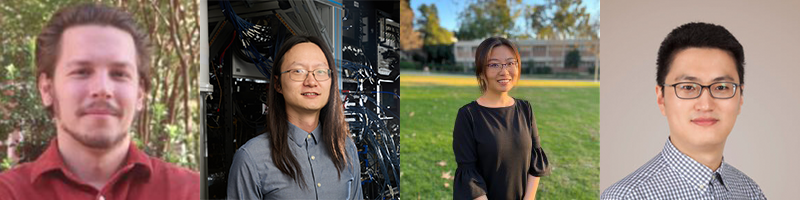

The UW Institute for Nano-engineered Systems (NanoES) has awarded four seed grants to UW researchers to use nanotechnology tools to develop new, innovative technologies and devices. Leo Brody, a postdoctoral scholar in chemical engineering; Mo Chen, an assistant professor in materials science and engineering; Ji Feng, a research scientist in mechanical engineering, and Quansan Yang, an assistant professor in materials science and engineering, will receive up to $10,000 to carry out work in UW’s Washington Nanofabrication Facility (WNF) and the Molecular Analysis Facility (MAF). The WNF and MAF are key nanotechnology facilities in the Northwest Nanotechnology Infrastructure, one of 16 sites in the NSF’s National Nanotechnology Coordinated Infrastructure (NNCI) program.

“We are excited by the diversity and creativity of the proposals submitted by these new UW researchers,” said Karl Böhringer, director of NanoES and professor of electrical and computer engineering and bioengineering at the University of Washington. “We’re eager to see how Leo, Mo, Ji and Quansan’s projects unfold and the impact they’ll make.”

Nanotechnology Seed Grants enable first-time facility users inside and outside the UW to build and characterize prototypes, obtain preliminary results, and conduct proof-of-concept studies. More information can be found here.

“Antiperovskite carbides as tuneable, oxidation-resistant catalysts with noble metal-like performance for waste plastic conversion,” by Leo Brody

Chemical upcycling waste plastics to value-added fuels and chemicals via catalytic hydrogenolysis and hydrogenation is a rapidly growing area of sustainable process engineering with numerous unexplored research directions. Transition metal carbides (TMCs) have long been recognized for exhibiting noble metal-like catalytic activity in hydrogenolysis and hydrogenation reactions despite comprising abundant and economically accessible metals such as molybdenum or tungsten. However, even trace amounts of oxygen at elevated temperatures cause TMCs to form stable metal oxides and consequently lose their essential metallic surface characteristics. This oxidation prevents prolonged catalytic operation and complicates fundamental insights into the active sites. Furthermore, regenerating TMCs typically requires gas mixtures containing hydrogen and alkanes to effectively recarburize the surface, yet full recovery of initial catalytic performance often remains unattainable. The primary limitation of binary TMCs as thermal catalysts stems from their thermodynamic tendency to form oxides and their restricted design space. Attempts to improve stability by doping the TMC with other metals offer only temporary solutions, as phase segregation inevitably occurs under operational conditions.

An ideal catalytic material would display metallic surface properties comparable to noble metals, comprise similarly affordable and abundant elements as TMCs, and resist oxidation during prolonged operation. Antiperovskite carbides potentially meet these criteria. Though significantly less studied than their electronically inverted counterparts, antiperovskite carbides exhibit remarkable properties, including superconductivity and promising electrocatalytic activity for reactions such as OER and HER. Antiperovskite carbides (general formula X3AC, where X is a transition metal cation, and A is typically a Group III or IV anion) may offer design flexibility analogous to perovskites. They can be doped with foreign cations, enabling strain engineering to precisely tune catalytic properties while preserving structural integrity – potentially even under oxidizing environments. This robustness arises from their unique combination of ionic and covalent bonding networks and rigid electronic structures. Despite these potential benefits, their application in thermal catalysis remains completely unexplored, and a comprehensive characterization of their bulk and surface behavior in oxidizing atmospheres has yet to be undertaken.

Successful completion of this work will enable the synthesis of low-cost, earth-abundant catalytic materials as viable alternatives to the precious platinum group metals widely used in waste plastic conversion schemes. The novelty of these materials and their application to waste plastic upcycling are poised to generate significant research interest and attract new users and collaborators to the NNI network.

“A novel all-planar, subtractive process for fabricating high-quality Josephson Junctions in superconducting qubits,” by Mo Chen.

Superconducting Josephson Junctions (JJs) are the key building blocks of superconducting qubits, providing the necessary nonlinearity with minimal dissipation. However, current JJ fabrication relies on a lift-off-based process, requiring precise angled e-beam evaporation in a specialized tool—a technique incompatible with the standard CMOS process. This limits resilient utility-scale manufacturing of superconducting qubits.

Recent advancements, such as tri-layer JJ fabrication and overlay JJ processes, have demonstrated the feasibility of fully planar JJ fabrication. While promising, these methods introduce significant challenges, including multiple lithography steps and exposure of the JJ barrier layer to ambient conditions, which leads to contamination and defects. Addressing these limitations in a planar process is critical to improving the performance and reproducibility of JJs and superconducting qubits fabrication.

“Zr-MOFs for electrochemical PFAS detection,” by Ji Feng.

Per-and polyfluoroalkyl substances (PFAS) contamination in groundwater is a growing concern due to its persistent, toxic, and bioaccumulative nature. Measuring PFAS concentration at the groundwater site is crucial for assessing contamination levels, evaluating health risks, and guiding remediation efforts. Traditional methods for measuring PFAS levels, such as transporting samples to EPA-certified labs for LC-MS/MS analysis, are costly ($300-600 per sample), time-consuming, and impractical for real-time monitoring. Developing real-time PFAS sensors can reduce sample preparation time and analytical costs and provide real-time in-operando PFAS monitoring. The diverse chemical structures, low concentrations, and lack of optical or electrochemical properties of PFAS are challenges for sensing. Existing sensing methods, such as fluorescence and electrochemical sensors, often suffer from insufficient sensitivity and selectivity, particularly in detecting short-chain PFAS.

Our strategy addresses these challenges using Zr-MOF-modified CNT FETs for real-time PFAS sensing. FETs show advantages such as high sensitivity, real-time detection, and compact size. To date, a β-cyclodextrin (β-CD) modified reduced graphene oxide (rGO) FET sensor has achieved a limit of detection (LOD) of 0.25 ppt for PFOS in tap water, highlighting the potential of modifying FETs with suitable receptors to improve PFAS sensitivity. We propose incorporating different Zr-MOFs as receptors to enhance sensitivity when detecting various PFAS compounds. Zr-MOFs are emerging absorbents for PFAS because they can rapidly capture both short- and long-chain PFAS and exhibit excellent chemical and thermal stability. Our strategy is novel, as there has been no research on MOF-modified FETs for PFAS sensing, and the adsorption of various PFAS compounds from mixtures on MOFs has yet to be explored.

This proposal aims to fabricate Zr-MOF-modified CNT FET sensors and gather preliminary data on their PFAS capturing and sensing performance. The data obtained will inform the design of sensor arrays, which can be further integrated with machine learning algorithms to address the sensor’s selectivity challenges. The project could lead to the development of portable, cost-effective, and highly sensitive sensors for on-site PFAS detection, facilitating more efficient monitoring of contaminated water sources.

“10-nm-resolution, multi-material, dynamically tunable 3D meta-volumes by molecular-guided, multi-photon patterning in shrinkable scaffolds,” by Quansan Yang.

Nanophotonics and related fields urgently require a fabrication tool that produces meta-volumes (3D analogs of 2D metasurfaces) with nanoscale precision to control optical properties at each point. Such precision would enable applications across a broad wavelength range, including the visible spectrum. Moreover, the ability to dynamically tune these optical properties would greatly expand possibilities in optical computing, non-linear programming, and other adaptive photonic systems. However, existing direct laser writing techniques, such as multi-photon polymerization, remain fundamentally limited by the optical diffraction limit (typically sub-micron resolution or larger) and by multi-material integration and structural complexity challenges. Recently, implosion fabrication has emerged as a promising alternative, enabling the creation of complex, non-self-supporting 3D geometries with ~50 nm resolution by shrinking pre-patterned scaffolds deposited with specific nanomaterials. Yet, these methods still suffer from critical limitations: an inability to modulate the refractive index, restricted multi-material compatibility, and a lack of integrated dynamic control over material properties – all of which constrain their broader utility in nanophotonics.

To address these challenges, I propose a next-generation 3D nanofabrication platform that introduces three core innovations: (1) custom-designed photosensitizer molecules with orthogonal light-sensitive properties, enabling muIti-material photoprotein and subsequent complementary conjugation chemistries that can modulate refraction, reflection, and transmission at each point of the scaffolds ; (2) incorporation of photochromic or saturable absorber compounds to achieve dynamic tuning of optical properties, also at each point of the scaffolds; and (3) engineered scaffold materials featuring degradable crosslinkers to achieve enhanced shrinkage, enabling resolutions down to ~10 nm. This transformative approach will enable the fabrication of complex, multi-material 3D meta-volumes with ~10 nm resolution and tunable optical behavior.

We aim to use such a platform to create all-optical machine-learning devices for non-linear visible-wavelength optical computing. By combining nanoscale precision, muIti-material integration, and dynamic control in a single platform, our method opens new frontiers in nanophotonics, optical computing, biosensing, bioimaging, and beyond – poised to revolutionize 3D nanofabrication and catalyze innovations across both academia and industry.